This article will give you an overview of what flutes are, and how to choose the cutter with the right number of flutes for your application.

< Previous | List | Next >

What is a flute

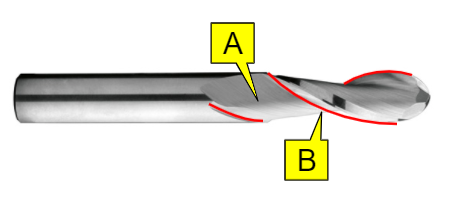

The troughs between the cutting edges of a routing bit are called “flutes”.

A: Flute

B: Cutting edges (in red)

The flutes have many functions:

-

The edges of the flutes on the router cutter are designed to cut material (unlike on drill bits).

-

The angle of the flutes have an important finishing effect on the top and bottom surfaces of the stock material (we’ll cover this later in this guide).

-

Flutes that are in a spiral or helix shape provide a path for the cut material (chips) to evacuate from the stock material, as the routing bit moves through it.

|

|

Unlike drill bits, flutes can push the chips either up, or down, or both up and down simultaneously (forcing chips into the midplane of the stock’s thickness).

|

Number of flutes

The most commonly used router cutters have 2, 3, or 4 flutes.

|

|

In this section, we will focus on choosing the number of flutes for a spiral cutter, and the effect flute number has on chip evacuation.

|

When you use a cutter with more flutes, the channels will subsequently be narrower and shallower. This means that any chips produced in cutting need to be small enough to travel along them. You can make chips smaller by reducing the feed rate.

Red indicates width of flutes, and subsequent maximum chip size:

|

|

Flutes evacuate chips from the worktop, and these chips take a significant amount of heat with them. It is therefore important that chip evacuation is as effective as possible.

|

Consider your application

The ideal number of flutes will change depending on your application. When choosing a cutter, you should consider:

-

Material: softer materials need fewer flutes than harder materials.

-

Surface finish: a cutter with more flutes, and therefore more cutting edges, will result in a better surface finish.

-

Feed rate: this will need to be adjusted depending on the strength or your cutter, and to allow for effective chip evacuation.

Materials

Use this information as a starting point for choosing your cutters, but also remember that you may want to adjust flute numbers for surface finish, type of material, and the shape of cutter you are using.

Hard materials

Cutters with more flutes work well for harder materials. They tend to have a larger core (due to their geometry), and are therefore stronger than cutters with fewer flutes. This makes them a better choice for harder materials, where you may already be using a slower feed rate and making smaller chips that can travel along the flutes.

For harder materials, consider cutters with 4 or more flutes.

Soft materials

Cutters with fewer flutes work well for softer materials, which the cutter can move through faster, whilst evacuating larger chips through the flutes. However, bear in mind that fewer flutes will result in a rougher surface finish, and the body of the cutter will be weaker.

For softer materials, consider cutters with 2 or 3 flutes.

Fibrous materials

If you are cutting more fibrous materials that create strands, use more flutes to reduce the amount of “stringing”.

For a soft plywood, a cutter with 3 flutes would be a good choice.

Feed rates

You may have seen that the rule of thumb is “more flutes more feed”, but this is not always the case. For cutters with lots of flutes, feed rates may even need to be much slower.

A cutter with more flutes is stronger, and will be better at withstanding the forces of higher feed rates.

However, if the feed rate is too high, the flutes will not be big enough to evacuate chips effectively, resulting in overloading of the tool and overheating at the cutting site.

< Previous | List | Next >