SmartBench is different to traditional CNC machines due to its innovative mechanical design.

< Previous | List | Next >

Material clamping technology

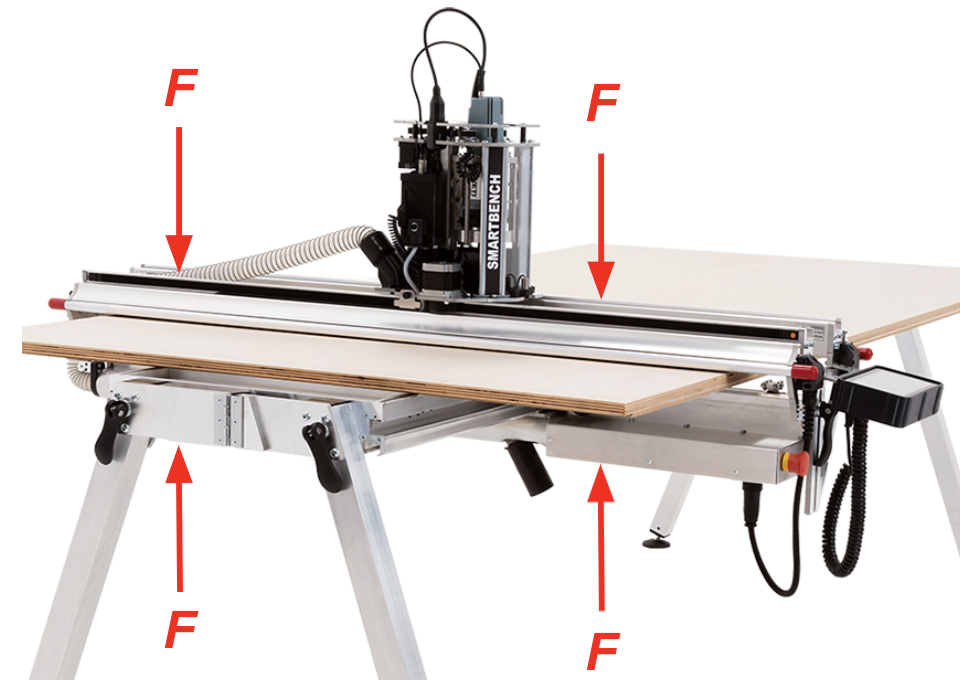

SmartBench is designed differently from other CNC machines to incorporate what we call “material clamping technology”.

Our patented design works by clamping the material between the upper and lower beam; this intrinsic clamping force gives SmartBench the rigidity it needs to withstand forces generated by routing (without needing to be big or bulky).

|

|

The system consists of 2 beams which both have sets of rollers. The roller sets run along the bottom of your spoilboard and the top of the material, clamping both together.

The resultant clamping force holds everything in place around the spindle while it is routing.

|

F: Clamping force

This technology is what makes SmartBench deployable, affordable and incredibly space efficient.

We have a video which explains this a little more here:

Mechanical structure

SmartBench has industrial-grade 3-axis CNC control.

We manufacture SmartBench using an aluminium tooling plate and custom extrusions for the best combination of weight and rigidity.

The X and Y axis move using a cammed wheel system, along with an industrial standard rack and pinion drive.

The motion along the Z axis is driven using a screw drive.

The Standard and Precision models use a single lead screw, and the PrecisionPro uses two for extra rigidity in the Z axis.

Reduced leverage of the tool

SmartBench does not use the conventional overhead gantry approach to support the spindle, unlike other CNC machines.

Traditional CNC

Traditional CNC machines have a longer distance between the spindle mounting and the tool, meaning they have to be more rigid to resist the extra leverage of the longer tool.

SmartBench

SmartBench holds the tool much closer to the work surface; this means that the leverage between the tool and the Z axis bearings is greatly reduced, and SmartBench’s application of force is far more efficient.

< Previous | List | Next >