This article will show you the differences between each of the SmartBench models, so that you can choose the features that are right for you.

< Previous | List | Next >

We offer 3 SmartBench models: PrecisionPro and PrecisionPro +

|

Features

|

PrecisionPro

|

PrecisionPro+

|

PrecisionProX

|

|

Spindle

|

SC1 1kW

|

SC2 1kW

|

SC2 1kW

|

|

Motor Speed Control

|

✓

|

✓

|

✓

|

|

Auto stop if spindle overloads

|

✓

|

✓

|

✓

|

|

Realtime overload display

|

✓

|

✓

|

✓

|

|

Dual lead screw Z Axis

|

✓

|

✓

|

✓

|

|

Laser X/Y Datum Point

|

✓

|

✓

|

✓

|

|

Part Precision +0.5mm or better

|

✓

|

✓

|

✓

|

|

Collect type

|

ER 16

|

ER 16

|

ER 16

|

|

10mm Max shank diameter

|

✓

|

✓

|

✓

|

|

Job Recovery

|

✓

|

✓

|

✓

|

|

Dust shoe version

|

Standard

|

Standard

|

Bigfoot

|

|

Console Ver.

|

Version 2

|

Version 2

|

Console XL

|

|

YetiPilot (AI Cutting)

|

-

|

✓

|

✓

|

|

SmartManager

|

Optional Extra

|

Included In Purchase

|

Included In Purchase

|

|

SmartTransfer

|

✓

|

✓

|

✓

|

|

Max Material Size

|

2500mm x 1250mm

|

2500mm x 1250mm

|

2500mm x 1250mm

|

|

Pack Down time

|

3 Minutes

|

3 Minutes

|

3 Minutes

|

|

Available Sizes

|

Mini / Standard

|

Mini / Standard

|

Mini / Standard

|

PrecisionPro

SmartBench Precision is our mid-range model, with digital spindle control and an ER16 collet system.

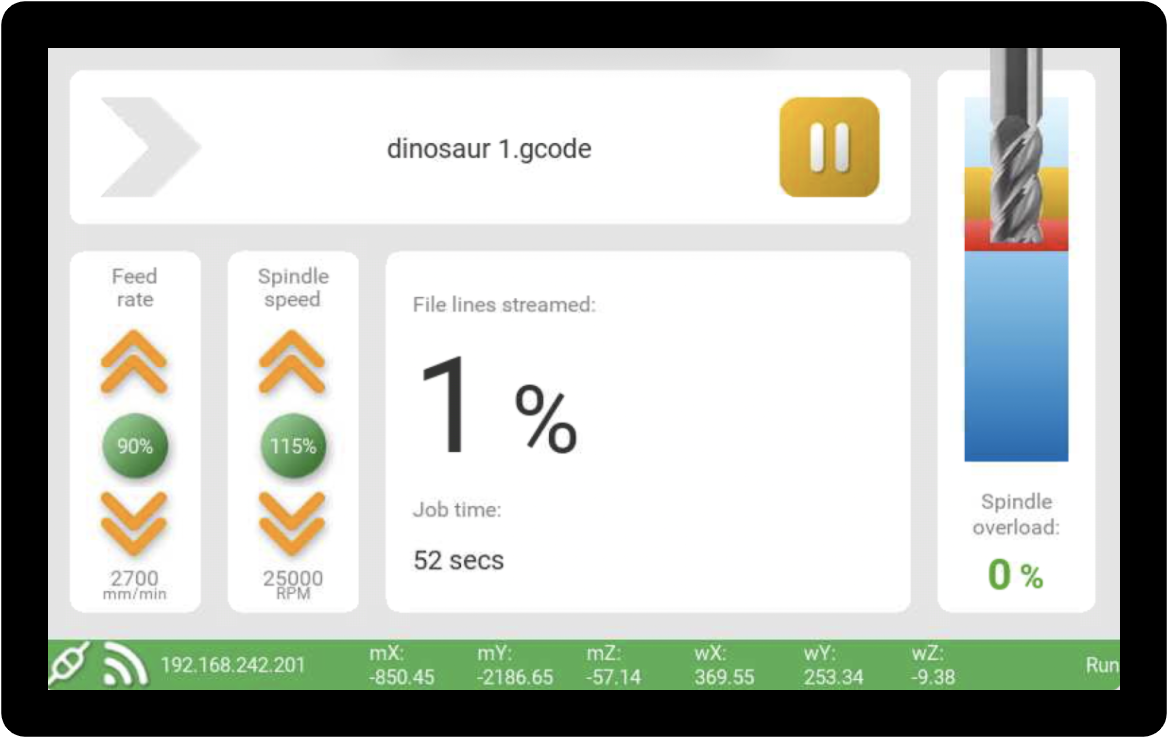

Digital spindle speed control

Adjust feeds and speeds throughout the job, using commands in the job file or console controls.

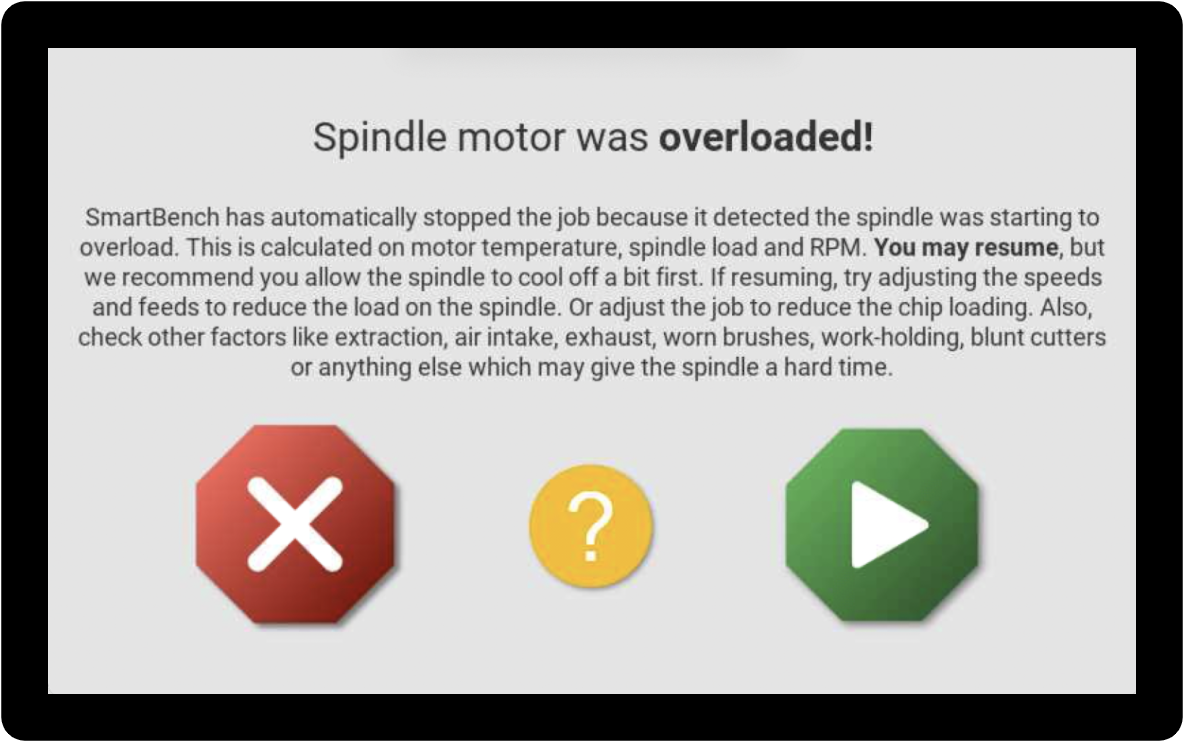

Overload detection

SmartBench will automatically detect whether the spindle is working too hard, and will auto-pause the job to prevent overload.

Laser datum

PrecisionPro comes equipped with a laser on the front of the Z Head for XY datum setting.

it’s easy to see exactly where the centre of the laser crosshair sits over your target, making datum setting much faster - perfect for quick turnarounds.

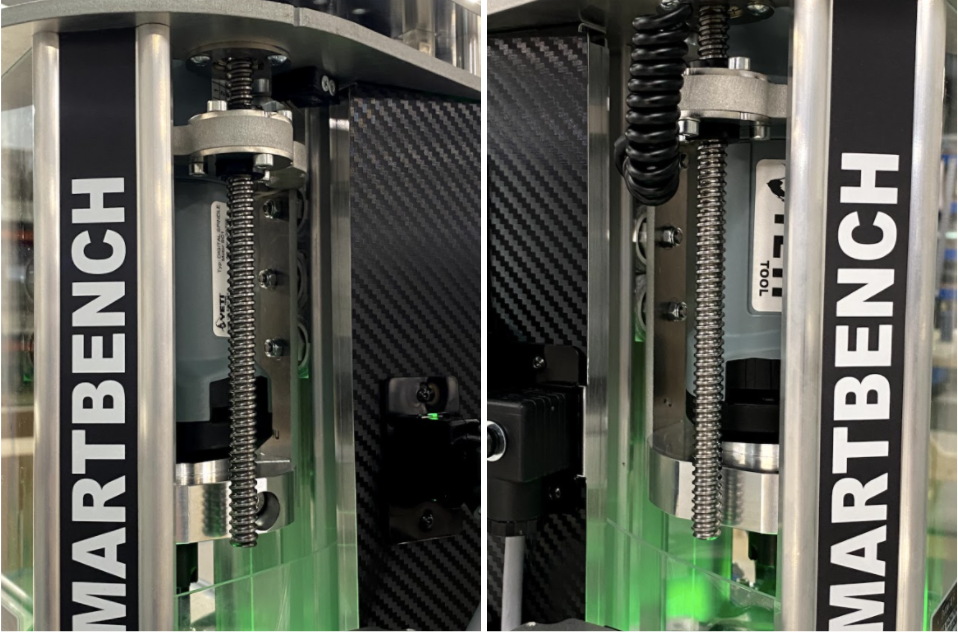

Dual Z axis lead screws

The dual lead screws give more restraint to the Z axis, reducing deflection during plunges and retracts.

Job recovery

Job save feature give you the option to resume your operation to recover your job if you had any issues while machining:

Incorrect cutting strategy

Z height was incorrectly set

Tool breakage during mid-job

Obstruction in cutting path

Realtime on-screen spindle monitoring

You will be able to see the load on the spindle in real time, in increments of 20%. This gives you an early indication if you need to adjust the feeds and speeds during the job.

PrecisionPro +

It has all the features of PrecisionPro model additionally it is equipped with advanced hardware to make your machining even more productive.

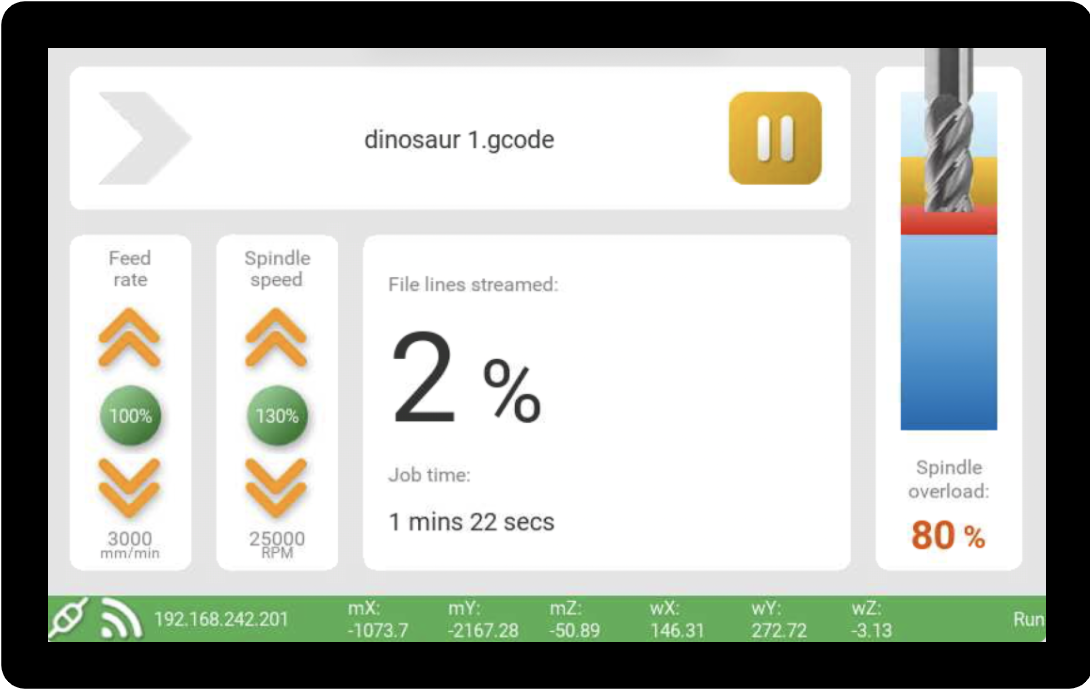

What does YetiPilot do?

Yetipilot, developed by Yeti Tool for SmartBench, is the latest technology in CNC control. It uses cutting edge electronics to automatically adjust SmartBench’s feed rate to suit the job.

So if the spindle motor is under too much stress (e.g. the cutter is becoming blunt, or cutting a full face/ deep section) YetiPilot will automatically slow SmartBench’s feed rate down. Similarly, if the spindle motor is not registering much power (e.g. shallow cut, or pessimistic feed rate in the GCode), YetiPilot will speed SmartBenches feed rate up.

This makes life easier for new users who may not be familiar with choosing the right feeds and speed, and also enables real-time optimisations not previously possible in standard CNC operation.

See Yeti Tool’s “Tech Demo” video to see YetiPilot in operation:

The top model of Smartbench introduces a larger console XL screen size, video demonstrating this here

And also a larger dust shoe designed for industrial extraction systems, video demonstrating this here