This article will detail on how to prepare your Z Head before undertaking any servicing or wheel replacement.

< Previous | List | Next >

Tools required

You will need the following tools for repair/ maintenance:

A: 4mm torx driver

B: 10mm spanner

Preparing your Z Head

The X axis wheels and pinions are on the base of the Z Head, so we will need to remove it from the Upper X Beam to access them.

Make sure SmartBench is powered off (click here to learn more about correct power down procedure).

Remove the spindle from the Z Head first if you have one inside the Z Head. Click here to learn more about this.

Remove the Z Head from the Upper X Beam. Click here to learn how.

C: Spindle

D: Z Head

E: Upper X Beam

F: Y Bench

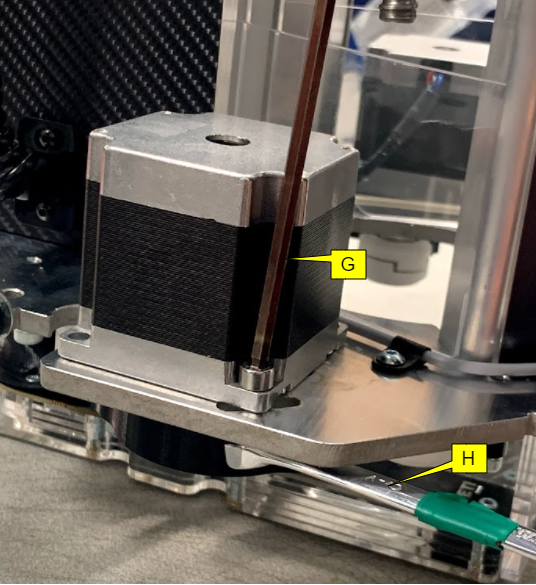

The motor is set to allow the pinion to mesh with the rack. However, when undertaking maintenance, you will need to rotate the pinions slightly away from the racks. This will prevent damage to the rack and pinion.

To rotate the motor pinion, first slacken the hex bolt by using a 4mm torx driver and 8mm spanner and repeat the same step on other sides of the Z Head motor.

G: 4mm torx driver

H: 8 mm spanner

loosen off the 4mm hex socket at the top of the motor on both sides of the Z Head.

Once you have loosen all the screws rotate the motor as shown in the picture and repeat this step for the other motor.

E: Z Head motor

Replacing wheels on Z Head

Now go to the next article by clicking here to replace your old wheels with the new ones.

< Previous | List | Next >