This article describes the function of Interrupt bars, and why you might need to cancel a job if an interrupt bar has been triggered.

< Previous | List | Next >

Overview

SmartBench’s Upper X Beam has two Interrupt bars. When they are pressed, SmartBench will stop and pause all active jobs or operations.

If there is an obstacle on the surface of the stock material, the Interrupt bars will detect it and pause SmartBench.

A: Interrupt bars

What happens when an Interrupt bar has been pushed?

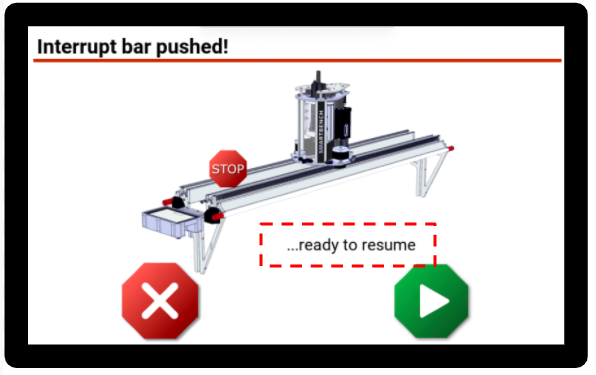

The “Interrupt bar pushed!” screen will appear on the Console.

|

|

Carefully check what caused the Interrupt bar to be pushed, and remove any obstacles.

Check that the Interrupt bars are no longer depressed, and are moving freely.

SmartBench will not allow you to resume if аn interrupt bar stays pushed.

|

SmartBench will tell you when it is ready to resume, and you can cancel or resume the job.

When do I need to cancel the job?

Even if the Interrupt bars detect an obstruction, they might not be able to stop SmartBench’s motion before the obstruction causes an axis to stall.

If an axis has stalled, SmartBench will have lost position. In this case you need to cancel the job, rehome, and resquare SmartBench before resuming any other operations.

If the axis did not stall, the job can simply be resumed when the obstacle has been removed.

|

|

SmartBench will decelerate after the Interrupt bars have made contact with the obstacle. Therefore, stalls are more likely to happen when SmartBench is travelling faster, as it will travel further before it comes to a full stop.

|

Examples of Interrupt bar events

It is important to diagnose the cause of the Interrupt bar push so that it can be resolved and handled appropriately.

Case study 1: Interrupt bars pushed for pausing a job

The Interrupt bar was pushed intentionally by the operator because the extraction was not working properly during the job.

This would be unlikely to cause a stall. After the operator has fixed their extraction issue, the job can be resumed.

Case study 2: Interrupt bars pushed by an fixed obstacle

The Interrupt bar was pushed by a screw which was not correctly fitted by the operator.

Even though SmartBench detected that there was an obstruction and stopped moving, it is likely that SmartBench still stalled in the process.

As it is hard to determine if the machine has lost steps and its position, it would be safest to cancel the job and start again.

< Previous | List | Next >