.< Previous | List | Next >

This procedure should be carried out in the event of:

-

a console reminder, or

-

the lead screw squeaking when moving

-

If the machine has not been used for a while because dust can buildup on the lead screws and the grease can "dry out"

-

This procedure is also best carried out alongside cleaning out the Z-Axis wheel channels

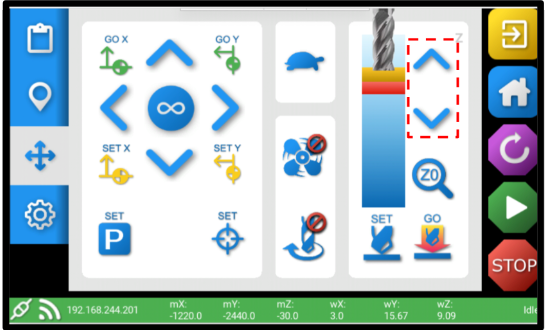

The reminders will look like this:

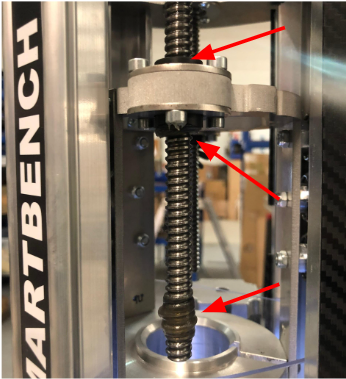

Clean away any debris that might have built up from the Z Axis lead screw we recommend using WD40 and a paintbrush

|

|

Use a grease that is thick enough to prevent fling-off onto other components when in operation. We recommend using a lithium-based grease (This is the grease we have found the best performance with and use in our factory).

|

|

|

If using a thick grease is inappropriate, for example due to high volumes of dust which may stick to the grease, you may use a thinner lubricant such as a PTFE. If you do choose to use a thinner lubricant you must reapply much more frequently (e.g. after every job).

|

Apply the grease fairly liberally along the whole length of the lead screw. This can be applied with a small brush.

Or, if using a spray grease, use tissue (or similar) to protect the rest of the Z Head and the Spindle motor from overspray.

The image below shows the correct amount of grease. This will even out as we move the axis in the next steps.

Cycle the Z axis up and down its full length a few times to spread the lubricant evenly around the threads of the lead screw. Use the jog buttons identified below.

Use the blue roll to wipe off any excess grease as it will attract dust to the lead screw. The excess will collect at either end of the lead screw and around the nut on the Spindle motor cage.

Once the lead screw (both lead screws on the PrecisionPro) have been lubricated you may clear the reminder by pressing “Ok! Z-head lubricated!”. This will automatically reset the reminder.