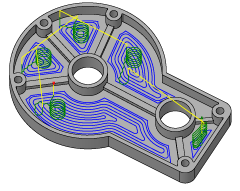

2D Pocket

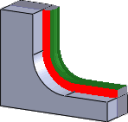

2D Pocket is a roughing operation with options for creating a finish pass. You can clear a cavity, open pocket or the area around a boss. The toolpath will resemble the shape of the boundary being machined. The machining area can be selected from Edges, Sketches or a Solid face. Includes options for taper walls and Pre-drilling entry positions.

Access: Ribbon > Manufacture workspace > 2D panel > 2D Pocket

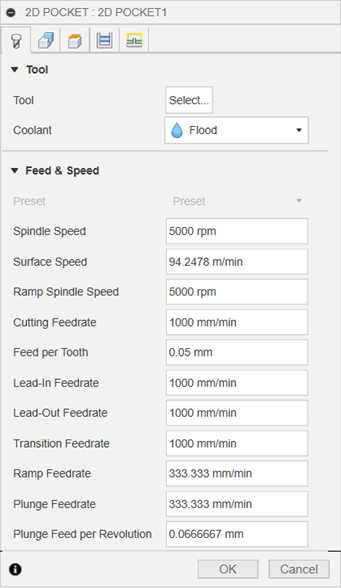

Tool tab settings

Tool tab settings

Coolant

Select the type of coolant used with the machine tool. Not all types will work with all machine postprocessors.

Feed & Speed

Spindle and Feedrate cutting parameters.

-

Spindle Speed - The rotational speed of the spindle expressed in Rotations Per Minute (RPM)

-

Surface Speed - The speed which the material moves past the cutting edge of the tool (SFM or m/min)

-

Ramp Spindle Speed - The rotational speed of the spindle when performing ramp movements

-

Cutting Feedrate - Feedrate used in regular cutting moves. Expressed as Inches/Min (IPM) or MM/Min

-

Feed per Tooth - The cutting feedrate expressed as the feed per tooth (FPT)

-

Lead-In Feedrate - Feed used when leading in to a cutting move.

-

Lead-Out Feedrate - Feed used when leading out from a cutting move

-

Ramp Feedrate - Feed used when doing helical ramps into stock

-

Plunge Feedrate - Feed used when plunging into stock

-

Feed per Revolution - The plunge feedrate expressed as the feed per revolution

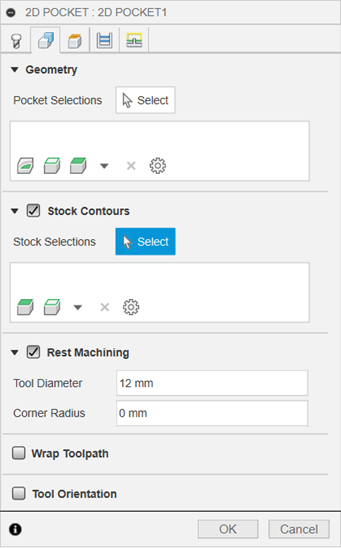

Geometry tab settings

Geometry tab settings

Geometry

|

|

Select Faces, Edges or Sketches. You can remove stock from the inside of a pocket or the outside of a standing boss.

-

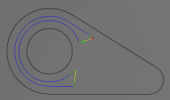

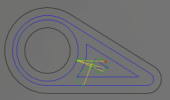

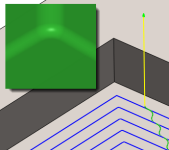

Closed Pocket Machining

-

Open Pocket Machining

-

Standing Boss Machining

|

Pocket Selection

Select any Face, Edge or Sketch to define the machining boundary. Use Edge selection for areas with holes or pockets inside of pockets. For standing bosses select the outer boundary of the boss and check the Stock Contours option shown below. The toolpath will be calculated between the selected boundary and the outer stock area.

|

|

Select Faces, Edges or Sketches. Use Edge selection for areas with holes or pockets inside of pockets.

-

Closed Pocket Face Selection

-

Open Pocket Face Selection

-

Standing Boss Edge Selection. Shown with stock boundary

|

Stock Contours

When checked, the toolpath is calculated to consider the boundaries of the defined Stock or a selected boundary. The default boundary is the Stock box specified in the Setup. You can also select Edges from the model or a Sketch boundary. This provides additional clearance for the Lead in and Lead out moves. This can limit or extend the stock machining area. Leave unchecked for closed boundary pockets.

Stock Selections - Select a closed boundary to define the machining area. No selection is needed to machine the Stock box specified in the Setup. Selecting a boundary larger than the stock extends the cutting area. This can be useful for irregular stock sizes. The selected machining boundary can be any shape.

|

|

Select Edges or Sketches to define the cutting boundary.

-

Calculated from the Stock - No selection required

-

A Sketch larger than the Stock extends the cutting area

-

The selected area can be any size or shape

Note: This is not a containment boundary, since the tool will approach from outside the selected area.

|

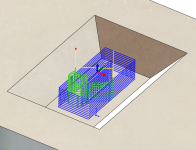

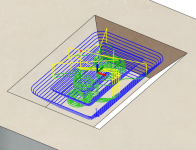

Rest Machining

Limits the operation to just remove material that a previous tool or operation could not remove.

|

Rest Machining ON

|

Rest Machining OFF

|

Tool Diameter

Specifies the diameter of the rest material tool.

Corner Radius

Specifies the corner radius of the rest material tool.

Tool Orientation

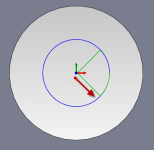

Specifies how the tool orientation is determined using a combination of triad orientation and origin options.

The Orientation drop-down menu provides the following options to set the orientation of the X, Y, and Z triad axes:

-

Setup WCS orientation - Uses the workpiece coordinate system (WCS) of the current setup for the tool orientation.

-

Model orientation - Uses the coordinate system (WCS) of the current part for the tool orientation.

-

Select Z axis/plane & X axis - Select a face or an edge to define the Z axis and another face or edge to define the X axis. Both the Z and X axes can be flipped 180 degrees.

-

Select Z axis/plane & Y axis - Select a face or an edge to define the Z axis and another face or edge to define the Y axis. Both the Z and Y axes can be flipped 180 degrees.

-

Select X & Y axes - Select a face or an edge to define the X axis and another face or edge to define the Y axis. Both the X and Y axes can be flipped 180 degrees.

-

Select coordinate system - Sets a specific tool orientation for this operation from a defined user coordinate system in the model. This uses both the origin and orientation of the existing coordinate system. Use this if your model does not contain a suitable point & plane for your operation.

The Origin drop-down menu offers the following options for locating the triad origin:

-

Setup WCS origin - Uses the workpiece coordinate system (WCS) origin of the current setup for the tool origin.

-

Model origin - Uses the coordinate system (WCS) origin of the current part for the tool origin.

-

Selected point - Select a vertex or an edge for the triad origin.

-

Stock box point - Select a point on the stock bounding box for the triad origin.

-

Model box point - Select a point on the model bounding box for the triad origin.

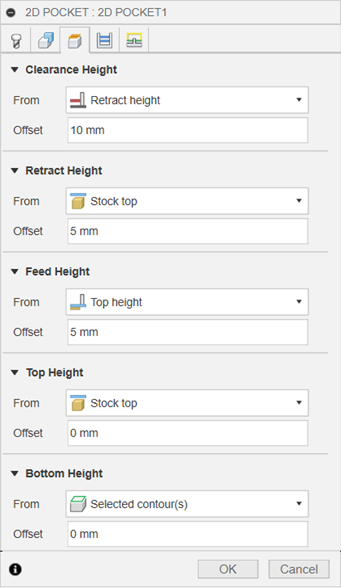

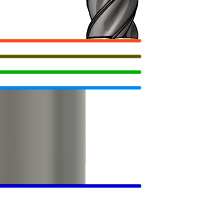

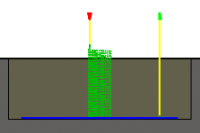

Heights tab settings

Heights tab settings

Clearance Height

The Clearance height is the first height the tool rapids to on its way to the start of the tool path.

Clearance Height

Clearance Height

-

Retract height: incremental offset from the Retract Height.

-

Feed height: incremental offset from the Feed Height.

-

Top height: incremental offset from the Top Height.

-

Bottom height: incremental offset from the Bottom Height.

-

Model top: incremental offset from the Model Top.

-

Model bottom: incremental offset from the Model Bottom.

-

Stock top: incremental offset from the Stock Top.

-

Stock bottom: incremental offset from the Stock Bottom.

-

Selected contour(s): incremental offset from a Contour selected on the model.

-

Selection: incremental offset from a Point (vertex), Edge or Face selected on the model.

-

Origin (absolute): absolute offset from the Origin that is defined in either the Setup or in Tool Orientation within the specific operation.

Clearance Height Offset

The Clearance Height Offset is applied and is relative to the Clearance height selection in the above drop-down list.

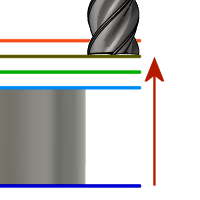

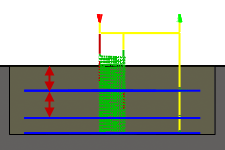

Retract Height

Retract height sets the height that the tool moves up to before the next cutting pass. Retract height should be set above the Feed height and Top. Retract height is used together with the subsequent offset to establish the height.

Retract Height

Retract Height

-

Clearance height: incremental offset from the Clearance Height.

-

Top height: incremental offset from the Top Height.

-

Bottom height: incremental offset from the Bottom Height.

-

Model top: incremental offset from the Model Top.

-

Model bottom: incremental offset from the Model Bottom.

-

Stock top: incremental offset from the Stock Top.

-

Stock bottom: incremental offset from the Stock Bottom.

-

Selected contour(s): incremental offset from a Contour selected on the model.

-

Selection: incremental offset from a Point (vertex), Edge or Face selected on the model.

-

Origin (absolute): absolute offset from the Origin that is defined in either the Setup or in Tool Orientation within the specific operation.

Retract Height Offset

Retract Height Offset is applied and is relative to the Retract height selection in the above drop-down list.

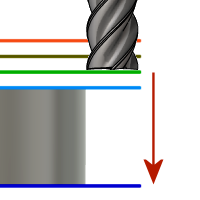

Feed Height

Feed height sets the height that the tool rapids to before changing to the feed/plunge rate to enter the part. Feed height should be set above the Top. A drilling operation uses this height as the initial feed height and the retract peck height. Feed height is used together with the subsequent offset to establish the height.

Feed Height

Feed Height

-

Clearance height: incremental offset from the Clearance Height.

-

Retract height: incremental offset from the Retract Height.

-

Disabled: disabling the Feed Height causes the tool to rapid down to the lead-in.

-

Top height: incremental offset from the Top Height.

-

Bottom height: incremental offset from the Bottom Height.

-

Model top: incremental offset from the Model Top.

-

Model bottom: incremental offset from the Model Bottom.

-

Stock top: incremental offset from the Stock Top.

-

Stock bottom: incremental offset from the Stock Bottom.

-

Selected contour(s): incremental offset from a Contour selected on the model.

-

Selection: incremental offset from a Point (vertex), Edge or Face selected on the model.

-

Origin (absolute): absolute offset from the Origin that is defined in either the Setup or in Tool Orientation within the specific operation.

Feed Height Offset

Feed Height Offset is applied and is relative to the Feed height selection in the above drop-down list.

Top Height

Top height sets the height that describes the top of the cut. Top height should be set above the Bottom. Top height is used together with the subsequent offset to establish the height.

Top Height

Top Height

-

Clearance height: incremental offset from the Clearance Height.

-

Retract height: incremental offset from the Retract Height.

-

Feed height: incremental offset from the Feed Height.

-

Bottom height: incremental offset from the Bottom Height.

-

Model top: incremental offset from the Model Top.

-

Model bottom: incremental offset from the Model Bottom.

-

Stock top: incremental offset from the Stock Top.

-

Stock bottom: incremental offset from the Stock Bottom.

-

Selected contour(s): incremental offset from a Contour selected on the model.

-

Selection: incremental offset from a Point (vertex), Edge or Face selected on the model.

-

Origin (absolute): absolute offset from the Origin that is defined in either the Setup or in Tool Orientation within the specific operation.

Top Offset

Top Offset is applied and is relative to the Top height selection in the above drop-down list.

Bottom Height

Bottom height determines the final machining height/depth and the lowest depth that the tool descends into the stock. Bottom height needs to be set below the Top. Bottom height is used together with the subsequent offset to establish the height.

Bottom Height

Bottom Height

-

Clearance height: incremental offset from the Clearance Height.

-

Retract height: incremental offset from the Retract Height.

-

Feed height: incremental offset from the Feed Height.

-

Top height: incremental offset from the Top Height.

-

Model top: incremental offset from the Model Top.

-

Model bottom: incremental offset from the Model Bottom.

-

Stock top: incremental offset from the Stock Top.

-

Stock bottom: incremental offset from the Stock Bottom.

-

Selected contour(s): incremental offset from a Contour selected on the model.

-

Selection: incremental offset from a Point (vertex), Edge or Face selected on the model.

-

Origin (absolute): absolute offset from the Origin that is defined in either the Setup or in Tool Orientation within the specific operation.

Bottom Offset

Bottom Offset is applied and is relative to the Bottom height selection in the above drop-down list.

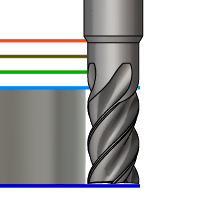

Passes tab settings

Passes tab settings

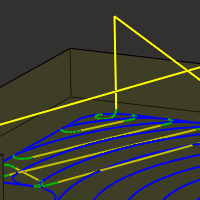

Tolerance

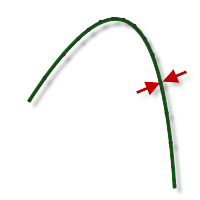

The tolerance used when linearizing geometry such as splines and ellipses. The tolerance is taken as the maximum chord distance.

|

Loose Tolerance .100

|

Tight Tolerance .001

|

CNC machine contouring motion is controlled using line G1 and arc G2 G3 commands. To accommodate this, CAM approximates spline and surface toolpaths by linearizing them creating many short line segments to approximate the desired shape. How accurately the toolpath matches the desired shape depends largely on the number of lines used. More lines result in a toolpath that more closely approximates the nominal shape of the spline or surface.

Data Starving

It is tempting to always use very tight tolerances but there are trade-offs including longer toolpath calculation times, large G-code files, and very short line moves. The first two are not much of a problem because CAM calculates very quickly and most modern controls have at least 1MB of RAM. However, short line moves, coupled with high feedrates, may result in a phenomenon known as data starving.

Data starving occurs when the control becomes so overwhelmed with data that it cannot keep up. CNC controls can only process a finite number of lines of code (blocks) per second. That can be as few as 40 blocks/second on older machines and 1,000 blocks/second or more on a newer machine like the Haas Automation control. Short line moves and high feedrates can force the processing rate beyond what the control can handle. When that happens, the machine must pause after each move and wait for the next servo command from the control.

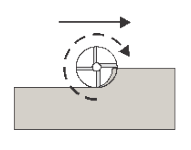

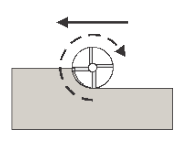

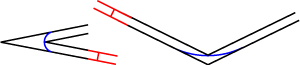

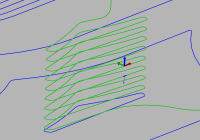

Sideways Compensation

This setting determines the side of the toolpath from which the tool center is offset. Choose between Left (climb milling) sideways compensation or Right (conventional milling) sideways compensation.

|

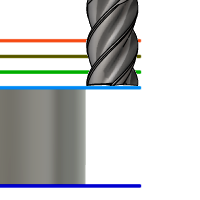

Left (climb milling)

Climb Milling

|

Right (conventional milling)

Conventional Milling

|

Climb milling can be thought of as the cutter ''rolling along'' the surface that it is cutting. This generally gives a better finish in most metals, but requires good machine rigidity. Using this method, chips start at maximum thickness and get thinner towards the end of the cut, meaning more heat in the chip and less in the part.

With conventional milling, the cutter is ''rotating away'' from the surface it is cutting. This method is more commonly used with manual or less rigid machines. It does have some advantages, and can even give a better finish when machining certain materials including some woods.

Finishing Passes

Enable to perform finishing passes using the side of the tool.

Note: This option is typically used when roughing and finishing is being done with the same tool.

|

With Finishing passes

|

Without Finishing passes

|

Number of Finishing Passes

Specifies the number of finishing passes.

Shown with three finishing passes

Shown with three finishing passes

Stepover

The maximum distance between finishing passes.

Leads on all Finishing Passes

Forces a full lead in and out on every finishing pass.

|

Enabled

|

Disabled

|

Note: Lead parameters are set on the Linking tab.

Finish Feedrate

The feedrate used for the final finishing pass.

Repeat Finishing Pass

Enable to perform the final finishing pass twice to remove stock left due to tool deflection.

Finishing Overlap

The finishing overlap is the distance that the tool passes beyond the entry point before leading out. Specifying a finishing overlap ensures that the material at the entry point is properly cleared.

|

No finishing overlap

|

0.25" finishing overlap

|

Note: The finishing overlap follows the selected contour, so it is safe to specify a large overlap.

Preserve Order

Specifies that features are to be machined in the order in which they were selected. When unselected, CAM optimizes the cut order.

Both Ways

Specifies that the operation uses both Climb and Conventional milling to machine open profiles.

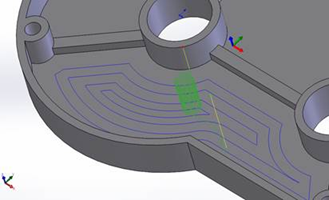

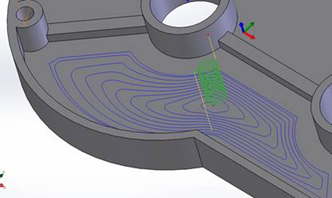

Maximum Stepover

Specifies the maximum horizontal stepover between passes.

Note: This is NOT the same as optimal load settings with adaptive clearing paths. With legacy 2D roughing, the tool still sees full cutter engagement when transitioning from one pass to the next.

|

Adaptive clearing

|

Legacy 2D clearing

|

Minimum Cutting Radius

With Minimum cutting radius set - Sharp corners in the toolpath are avoided minimizing chatter in finished parts.

Without Minimum cutting radius set - The toolpath attempts to remove material anywhere the selected tool can reach. This produces sharp corners in the toolpath that often leads to chatter in the machined part.

|

With Minimum cutting radius set

|

Without Minimum cutting radius set

|

Note: Setting this parameter leaves more material in internal corners requiring subsequent rest machining operations with a smaller tool.

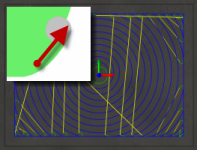

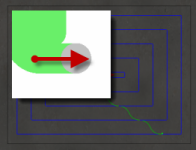

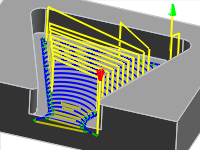

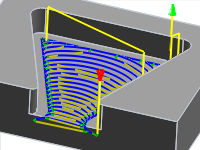

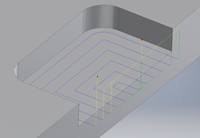

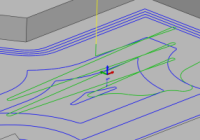

Use Morphed Spiral Machining

Enable to create a constant spiral move toolpath for the pocket. This can provide a smooth run on the machine.

|

Standard 2D pocket toolpath

|

Morphed spiral 2D pocket toolpath

|

Allow Stepover Cusps

When programming flat faces with a tool that has a radius in the corner, a cusp (or Scallop) can be produced between stepovers.

By default, the Maximum stepover value is overridden to insure that no stepover cusps are produced.

|

Allow stepover cusps disabled

|

Allow stepover cusps enabled

|

Above - Pocket machined with a 3/8" bullnose end mill @ .25" maximum stepover.

Smoothing Deviation

The maximum amount of smoothing applied to the roughing passes. Use this parameter to avoid sharp corners in the toolpath.

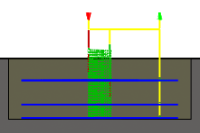

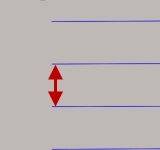

Multiple Depths

When selected multiple depths can be taken.

|

With Multiple Depth cuts

|

Without Multiple Depth cuts

|

Maximum Stepdown

Specifies the distance for the maximum stepdown between Z-levels. The maximum stepdown is applied to the full depth, less any remaining stock and finish pass amounts.

|

|

-

Final rough pass may be less than the Max Stepdown

-

Shown without finishing stepdown

-

Shown without additional Radial stock

|

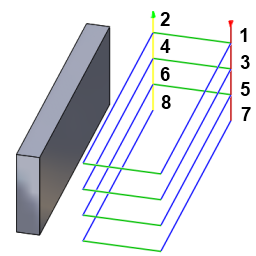

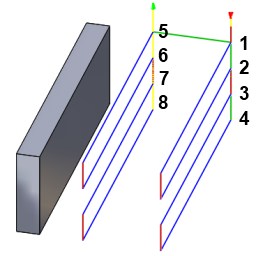

Finishing Stepdowns

The number of finishing passes using the bottom of the tool.

Shown with three finishing passes

Shown with three finishing passes

Finishing Stepdown

The size of each stepdown in the finishing passes.

Finishing stepdown

Finishing stepdown

Wall Taper Angle (deg.)

Specifies the taper angle of the walls.

Defining a slope angle can be used to machine features with a 2D strategy that would have otherwise required a 3D strategy.

Note: The slope angle is NOT driven by model geometry so it is possible that an error entering the slope angle can affect the finish machined part.

|

Slope angle @ 0 degrees

|

Slope angle @ 45 degrees

|

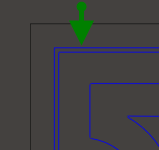

Geometry Selection

|

Bottom Selection

|

Top Selection

|

Note: When using a slope angle with the Adaptive Clearing strategy, geometry must be selected at the top of the pocket.

Use Even Stepdowns

Enable to create equal distances between machining passes.

Example: Suppose you are machining a profile with a depth of 23 mm and a maximum stepdown = 10 mm.

-

With Use Even Stepdowns enabled - you get three passes with the first value at -7.666 mm, the second at 15.3333 mm, and the third at -23 mm.

-

With Use Even Stepdowns disabled - again you get three passes, the first at -10 mm, the second at -20 mm, and the third at -23 mm.

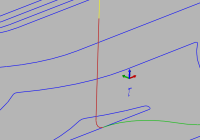

Order by Depth

Specifies that the passes should be ordered top down.

|

Disabled

|

Enabled

|

Order by Step

When enabled, each roughing and finishing step is machined to the full depth before moving to the next step.

|

Disabled

|

Enabled

|

Stock to Leave

|

Positive

Positive Stock to Leave - The amount of stock left after an operation to be removed by subsequent roughing or finishing operations. For roughing operations, the default is to leave a small amount of material.

|

None

No Stock to Leave - Remove all excess material up to the selected geometry.

|

Negative

Negative Stock to Leave - Removes material beyond the part surface or boundary. This technique is often used in Electrode Machining to allow for a spark gap, or to meet tolerance requirements of a part.

|

Radial (wall) Stock to Leave

The Radial Stock to Leave parameter controls the amount of material to leave in the radial (perpendicular to the tool axis) direction, i.e. at the side of the tool.

|

Radial stock to leave

|

Radial and axial stock to leave

|

Specifying a positive radial stock to leave results in material being left on the vertical walls and steep areas of the part.

For surfaces that are not exactly vertical, CAM interpolates between the axial (floor) and radial stock to leave values, so the stock left in the radial direction on these surfaces might be different from the specified value, depending on surface slope and the axial stock to leave value.

Changing the radial stock to leave automatically sets the axial stock to leave to the same amount, unless you manually enter the axial stock to leave.

For finishing operations, the default value is 0 mm / 0 in, i.e. no material is left.

For roughing operations, the default is to leave a small amount of material that can then be removed later by one or more finishing operations.

Negative stock to leave

When using a negative stock to leave, the machining operation removes more material from your stock than your model shape. This can be used to machine electrodes with a spark gap, where the size of the spark gap is equal to the negative stock to leave.

Both the radial and axial stock to leave can be negative numbers. However, the negative radial stock to leave must be less than the tool radius.

When using a ball or radius cutter with a negative radial stock to leave that is greater than the corner radius, the negative axial stock to leave must be less than or equal to the corner radius.

Axial (floor) Stock to Leave

The Axial Stock to Leave parameter controls the amount of material to leave in the axial (along the Z-axis) direction, i.e. at the end of the tool.

|

Axial stock to leave

|

|

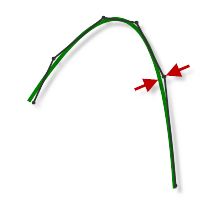

Both radial and axial stock to leave Specifying a positive axial stock to leave results in material being left on the shallow areas of the part. For surfaces that are not exactly horizontal, CAM interpolates between the axial and radial (wall) stock to leave values, so the stock left in the axial direction on these surfaces might be different from the specified value depending on surface slope and the radial stock to leave value. Changing the radial stock to leave automatically sets the axial stock to leave to the same amount, unless you manually enter the axial stock to leave. For finishing operations, the default value is 0 mm / 0 in, i.e. no material is left. For roughing operations, the default is to leave a small amount of material that can then be removed later by one or more finishing operations. Negative stock to leave When using a negative stock to leave the machining operation removes more material from your stock than your model shape. This can be used to machine electrodes with a spark gap, where the size of the spark gap is equal to the negative stock to leave. Both the radial and axial stock to leave can be negative numbers. However, when using a ball or radius cutter with a negative radial stock to leave that is greater than the corner radius, the negative axial stock to leave must be less than or equal to the corner radius. ## Smoothing Smooths the toolpath by removing excessive points and fitting arcs where possible within the given filtering tolerance.

|

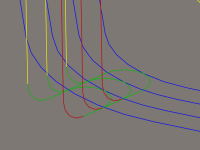

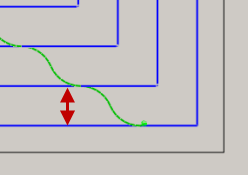

Smoothing Off

|

Smoothing On

|

Smoothing is used to reduce code size without sacrificing accuracy. Smoothing works by replacing collinear lines with one line and tangent arcs to replace multiple lines in curved areas.

The effects of smoothing can be dramatic. G-code file size may be reduced by as much as 50% or more. The machine will run faster and more smoothly and surface finish improves. The amount of code reduction depends on how well the toolpath lends itself to smoothing. Toolpaths that lay primarily in a major plane (XY, XZ, YZ), like parallel paths, filter well. Those that do not, such as 3D Scallop, are reduced less.

Smoothing Tolerance

Specifies the smoothing filter tolerance.

Smoothing works best when the Tolerance (the accuracy with which the original linearized path is generated) is equal to or greater than the Smoothing (line arc fitting) tolerance.

Note: Total tolerance, or the distance the toolpath can stray from the ideal spline or surface shape, is the sum of the cut Tolerance and Smoothing Tolerance. For example, setting a cut Tolerance of .0004 in and a Smoothing Tolerance of .0004 in means the toolpath can vary from the original spline or surface by as much as .0008 in from the ideal path.

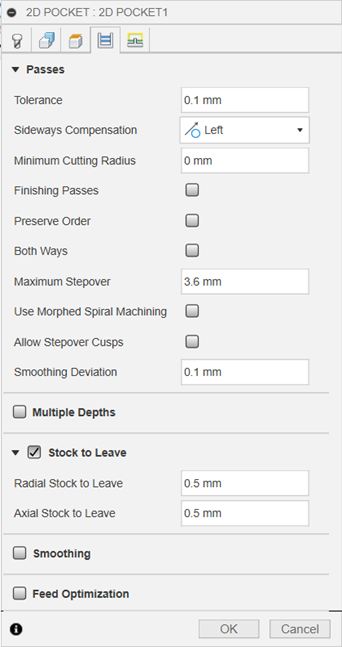

Feed Optimization

Specifies that the feed should be reduced at corners.

Maximum Directional Change

Specifies the maximum angular change allowed before the feedrate is reduced.

Reduced Feed Radius

Specifies the minimum radius allowed before the feed is reduced.

Reduced Feed Distance

Specifies the distance to reduce the feed before a corner.

Reduced Feedrate

Specifies the reduced feedrate to be used at corners.

Only Inner Corners

Enable to only reduce the feedrate on inner corners.

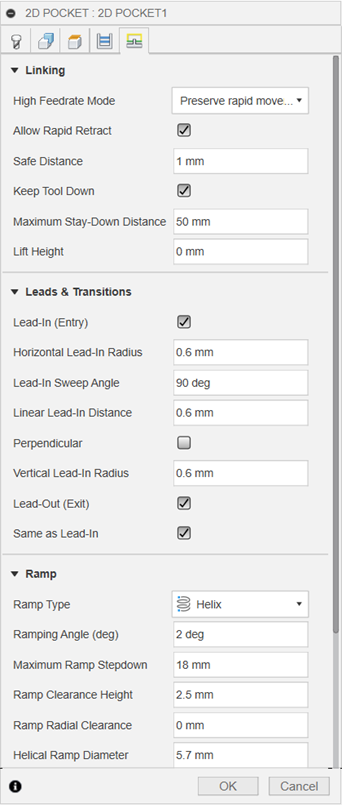

Linking tab settings

Linking tab settings

High Feedrate Mode

Specifies when rapid movements should be output as true rapids (G0) and when they should be output as high feedrate movements (G1).

-

Preserve rapid movement - All rapid movements are preserved.

-

Preserve axial and radial rapid movement - Rapid movements moving only horizontally (radial) or vertically (axial) are output as true rapids.

-

Preserve axial rapid movement - Only rapid movements moving vertically.

-

Preserve radial rapid movement - Only rapid movements moving horizontally.

-

Preserve single axis rapid movement - Only rapid movements moving in one axis (X, Y or Z).

-

Always use high feed - Outputs rapid movements as (high feed moves) G01 moves instead of rapid movements (G0).

This parameter is usually set to avoid collisions at rapids on machines which perform "dog-leg" movements at rapid.

High Feedrate

The feedrate to use for rapids movements output as G1 instead of G0.

Allow Rapid Retract

When enabled, retracts are done as rapid movements (G0). Disable to force retracts at lead-out feedrate.

Safe Distance

Minimum distance between the tool and the part surfaces during retract moves. The distance is measured after stock to leave has been applied, so if a negative stock to leave is used, special care should be taken to ensure that the safe distance is large enough to prevent any collisions.

Keep Tool Down

When enabled, the strategy avoids retracting when the distance to the next area is below the specified stay-down distance.

Maximum Stay-Down Distance

Specifies the maximum distance allowed for stay-down moves.

|

1" Maximum stay-down

|

2" Maximum stay-down distance

|

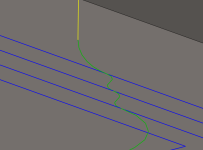

Lift Height

Specifies the lift distance during repositioning moves.

|

Lift height 0

|

Lift height .1 in

|

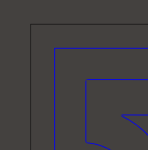

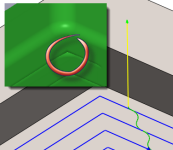

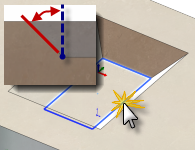

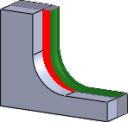

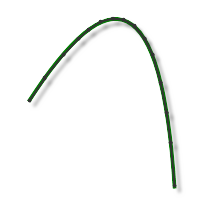

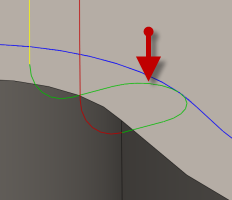

Lead-In (Entry)

Enable to generate a lead-in.

Lead-in

Lead-in

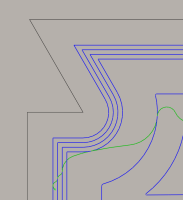

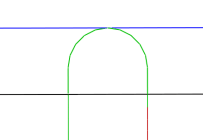

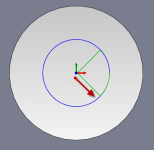

Horizontal Lead-In Radius

Specifies the radius for horizontal lead-in moves.

Horizontal lead-in radius

Horizontal lead-in radius

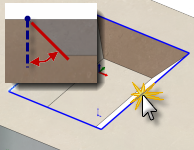

Lead-In Sweep Angle

Specifies the sweep of the lead-in arc.

Sweep angle @ 90 degrees

Sweep angle @ 90 degrees

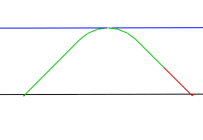

Sweep angle @ 45 degrees

Sweep angle @ 45 degrees

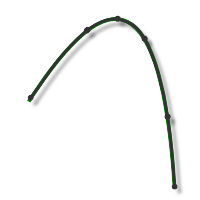

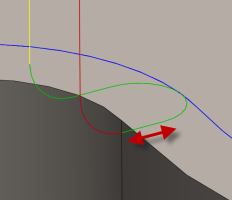

Linear Lead-In Distance

Specifies the length of the linear lead-in move for which to activate radius compensation in the controller.

Linear lead-in distance

Linear lead-in distance

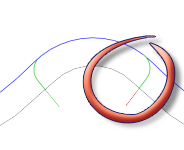

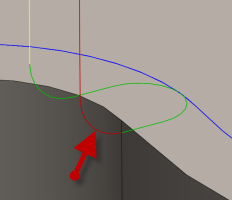

Perpendicular

Replaces tangential extensions of lead-in/lead-out arcs with a move perpendicular to the arc.

Shown with Perpendicular entry/exit

Shown with Perpendicular entry/exit

Example: A bore that has lead arcs that are as large as possible (the larger the arc the less chance of dwell mark), and where a tangent linear lead is not possible because it would extend into the side of the bore.

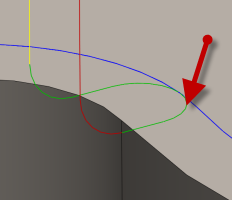

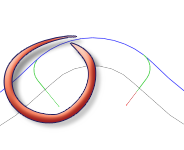

Vertical Lead-In Radius

The radius of the vertical arc smoothing the entry move as it goes from the entry move to the toolpath itself.

Vertical lead-in radius

Vertical lead-in radius

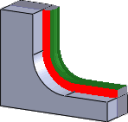

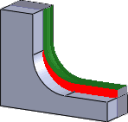

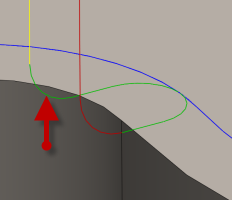

Lead-Out (Exit)

Enable to generate a lead-out.

Lead-out

Lead-out

Same as Lead-In

Specifies that the lead-out definition should be identical to the lead-in definition.

Linear Lead-Out Distance

Specifies the length of the linear lead-out move for which to deactivate radius compensation in the controller.

Linear lead-out distance

Linear lead-out distance

Horizontal Lead-Out Radius

Specifies the radius for horizontal lead-out moves.

Horizontal lead-out radius

Horizontal lead-out radius

Vertical Lead-Out Radius

Specifies the radius of the vertical lead-out.

Vertical lead-out radius

Vertical lead-out radius

Lead-Out Sweep Angle

Specifies the sweep of the lead-out arc.

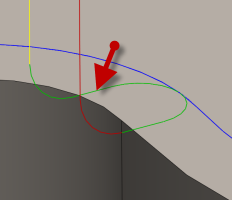

Perpendicular

Replaces tangential extensions of lead-in/lead-out arcs with a move perpendicular to the arc.

Shown with Perpendicular entry/exit

Shown with Perpendicular entry/exit

Example: A bore that has lead arcs that are as large as possible (the larger the arc the less chance of dwell mark) and where a tangent linear lead is not possible because it would extend into the side of the bore.

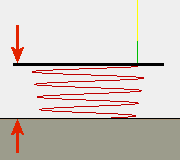

Ramp Type

Specifies how the cutter moves down for each depth cut.

|

Plunge Outside Stock

|

Zig-Zag

Notice the smooth transitions on the Zig-Zag ramp type.

|

|

Predrill

To use the Predrill option, Predrill location(s) must be defined.

|

Profile

|

|

Plunge

|

Smooth Profile

|

|

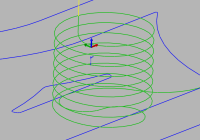

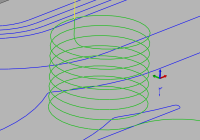

Helix

|

|

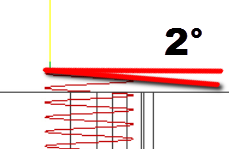

Ramping Angle (deg)

Specifies the maximum ramping angle of the helix during the cut.

Ramp Taper Angle

Creates a conical helix entry into the part. Excellent for chip clearance.

Maximum Ramp Stepdown

Specifies the maximum stepdown per revolution on the ramping profile. This parameter allows the tool load to be constrained when doing full-width cuts during ramping.

Ramp Clearance Height

The Height above the stock where the helix start its ramping move.

Helical Ramp Diameter

The maximum diameter to use for a helical entry into the cavity.

An optimal value causes the tool to overlap it's center, while still creating the maximum helical bore for the entry into the cavity. The goal is for good chip evacuation. If the value is bigger than the diameter of the tool it can leave a boss standing in the center of the helix.

|

Value of 1.8 x the Dia.

|

Value of 0.8 x the Dia.

|

Minimum Ramp Diameter

The smallest Helix Ramp Diameter that is acceptable.

This value should always be smaller than the Helix Ramp Diameter, so the system can calculate a range that fits the available pocket or channel. Smaller diameters can reduce the chip evacuation, create jerking machine motion and can cause tool breakage.

Predrill Positions

Select points where holes have been drilled to provide clearance for the cutter to enter the material.

Entry Positions

Select geometry near the location where you want the tool to enter.

Pages in this section